The decarbonization road has established since the Paris agreement signed on the March 2015 (COM n. 8 2015). Moreover, the steel industry represents an important economic pillar of the European economy. In 2020 crude steel production in the EU represents 7.6% (139.3 Mt) of the overall production globally (1828.2 Mt). The production of iron and steel is a major contributor to EU greenhouse gas emissions. The steel sector represented 4% of all EU emissions in 2017, and 23% of the whole manufacturing industry. For this reason, iron and steel industries play a key role in reducing the CO2 emissions of the European Area, through the full decarbonization of steel plants thanks to the availability of green electricity, hydrogen, CCUS infrastructure, sustainable raw and secondary materials, and alternative fuels. The main source of carbon dioxide in integrated steel plants is fossil coal, mainly used for metallurgical coke production. The scope of the BioCoDe project is the decarbonization of the industrial cokemaking process, replacing a fraction of the fossil coal coking mixture, with carbon-neutral biomass. This project aims to investigate, through experimental tests at different scales from the laboratory screening up to industrial scale trials. In addition, the influence of biomass introduction on environmental impact of the plant, process, products, and by-products. The BioCoDe project, beyond the objective of laying the foundations of a more green and sustainable industry, will enhance a local and European synergy between the agricultural and steel sectors, by promoting the local agricultural residues valorisation following circular and green economy principles in an industrial contest to be exploited in 2 different locations in 2 different Member States (MS). Such locations perfectly fit the aims of the project, considering two different types of forestry and agricultural waste, i.e., the mediterranean and the continental ones, to enlarge the range of steelworks which could adopt the BioCoDe approach.

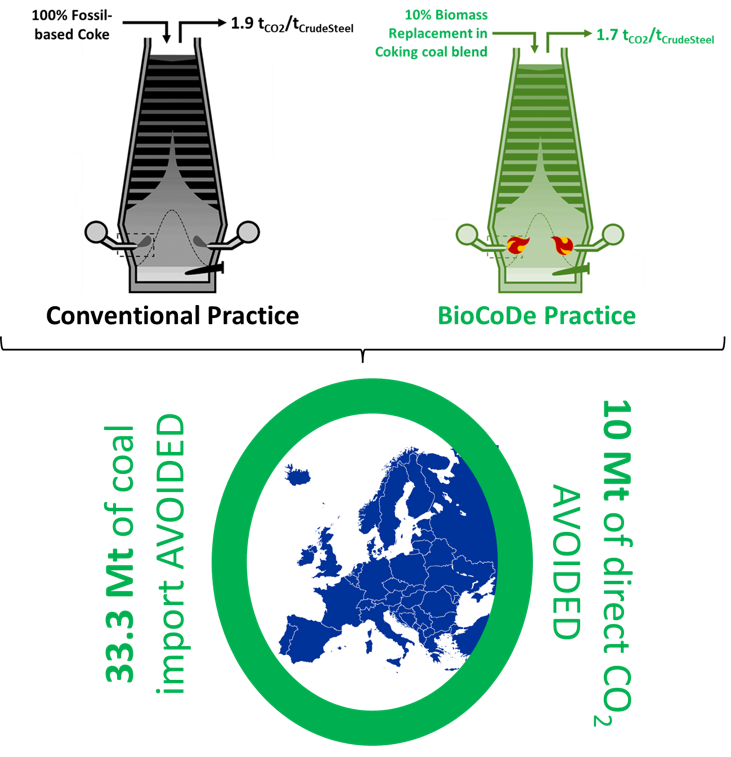

The general objective of the BIOCODE project is the partial substitution at industrial level of fossil coal with charcoal in the coke production up to 10%, to reduce CO2 emissions in hot metal process and to increase the sustainability of cokemaking process. This objective will be achieved via characterization of several types of biomasses and pre-treatment needed to obtain charcoal at laboratory and pilot scale. The large rage of conditions investigated in BioCoDe is necessary to find the most suitable conditions to substitute the highest amount possible of fossil fuel without reducing the quality of the final product. After this characterization, in BioCoDe the first industrial demonstration of biomass-based cokemaking process is demonstrated.

By achieving its general objective, BioCoDE aims to reduce the CO2 emissions in integrated steel plants by approximately 7.9% (considering the CO2 emission for BF 1.6 t/tHotMetal). The implementation of this concept will lay the foundation for creating a local biomass market in close synergy with local agriculture companies, which in the case of Taranto has been estimated to be between 50 to 100 M€ (considering an average price of biomass 150 €/t). If scaled up at EU level, the amount of CO2 avoided thanks to BioCoDe approach in EU will be of 10 Mt/y (0.28%). Moreover, a general market of biomass worth 2 B€, demonstrates the large impact of BIOCODE on the EU framework

The laboratory activities will be devoted to the characterization of biomass, biochar obtained by two different thermal treatment (pyrolysis and/or torrefaction) available from suppliers, and biochar properly produced from a selection of local biomass defined at the end of the first activity of biomass characterization and treatment selection. The pilot tests will be carried out in different size furnaces. The pilot campaign will define the most suitable biomass/biochar to be used for industrial tests and will provide to define the best type of material for the steel production. AdI and tkSE will define coal blend mixtures to be used as references and for addition of biomass and biochar selected.